Introduction to Evaporators

Evaporators are critical pieces of equipment in various industries, including food processing, pharmaceuticals, and chemical manufacturing. They are used to concentrate solutions by evaporating the solvent, typically water, from the solution. The efficiency and effectiveness of this process can significantly impact the overall production costs and product quality. There are different types of evaporators, but two common types are single-effect and multiple-effect evaporators. Understanding the differences between these two types is essential for selecting the right equipment for specific industrial applications.

Single-Effect Evaporators

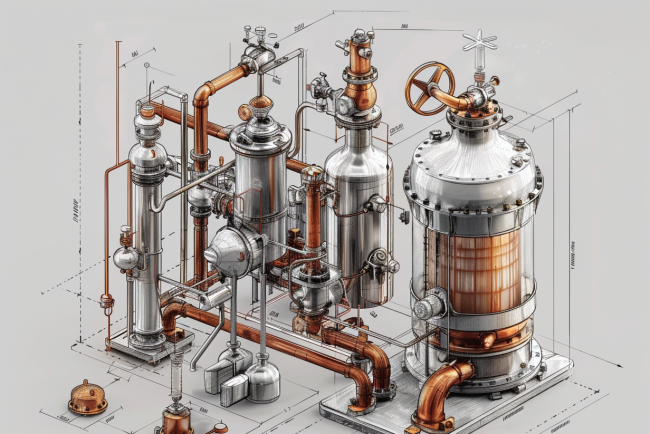

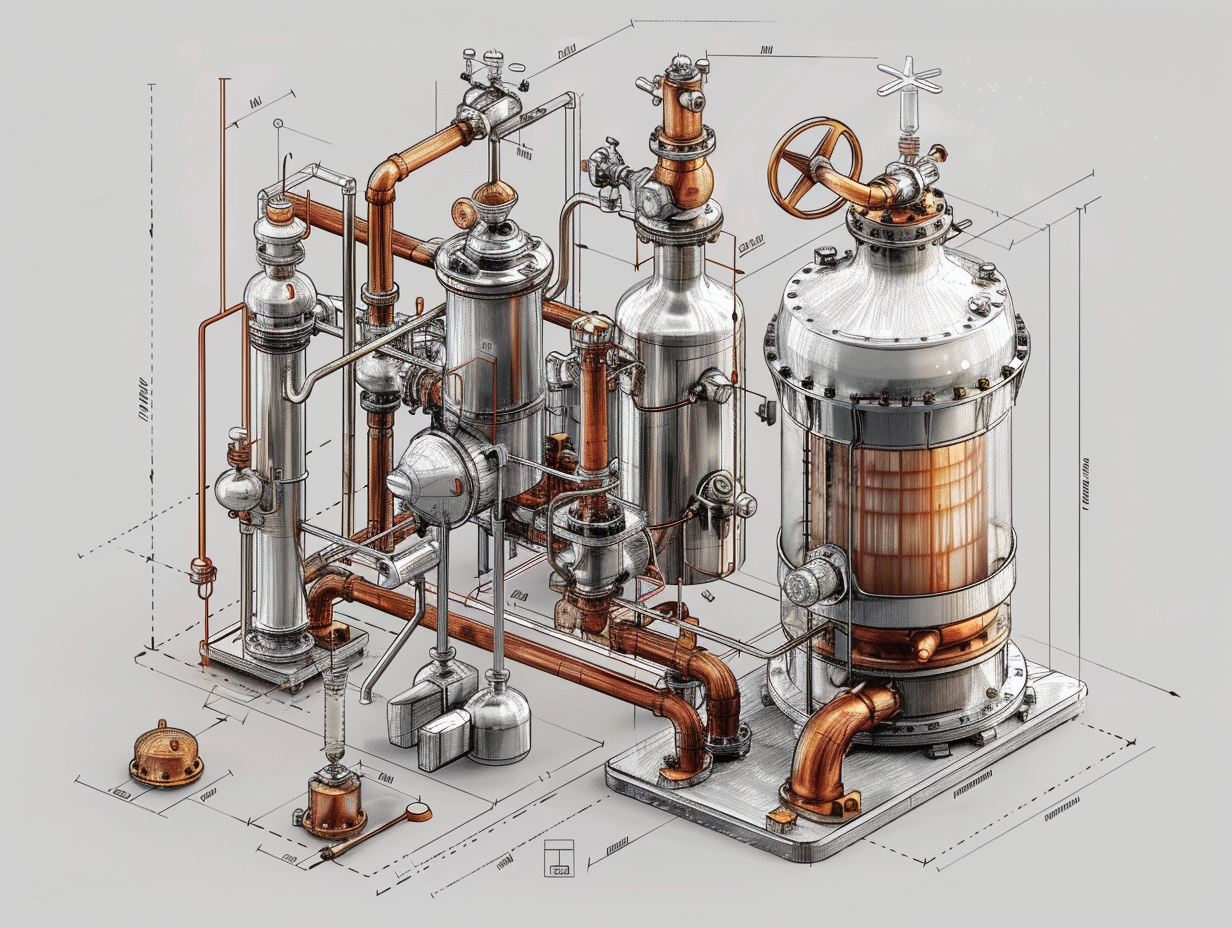

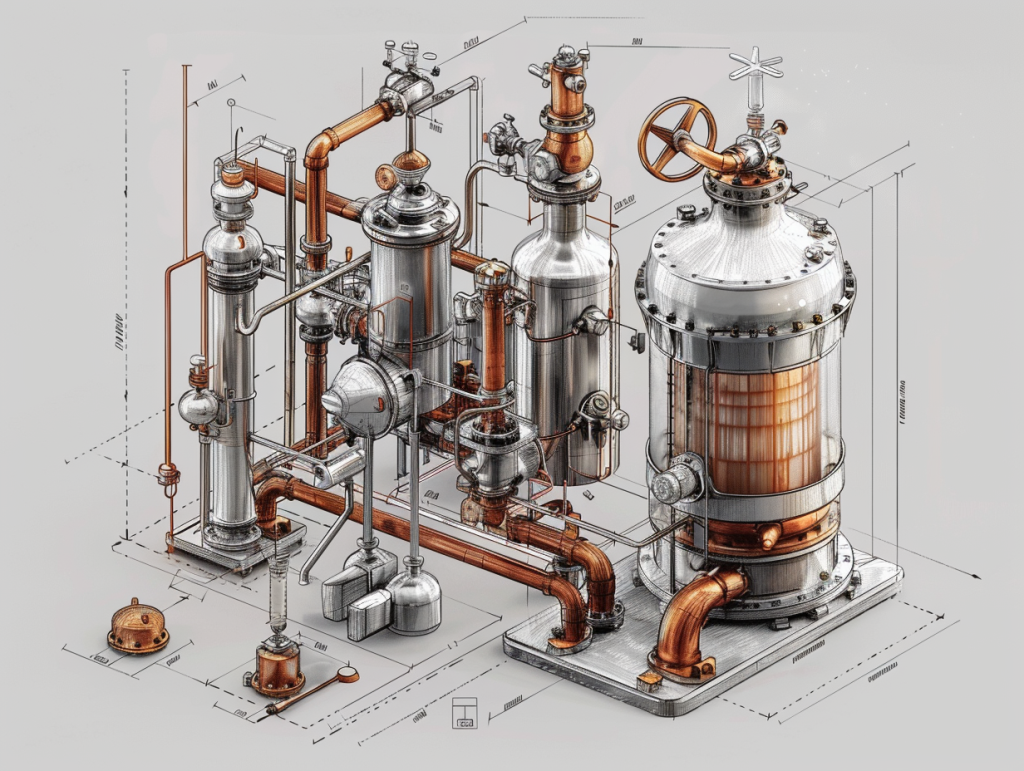

Definition and Working Principle

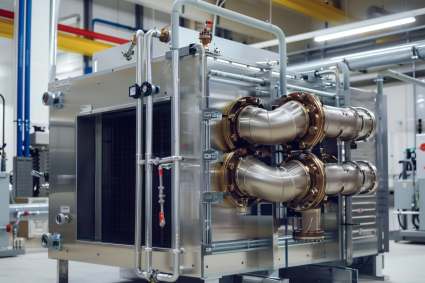

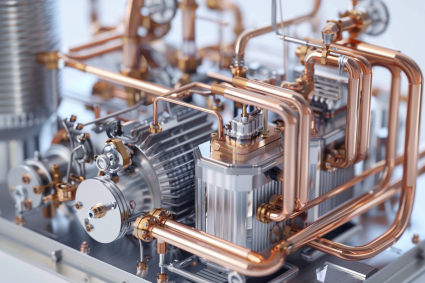

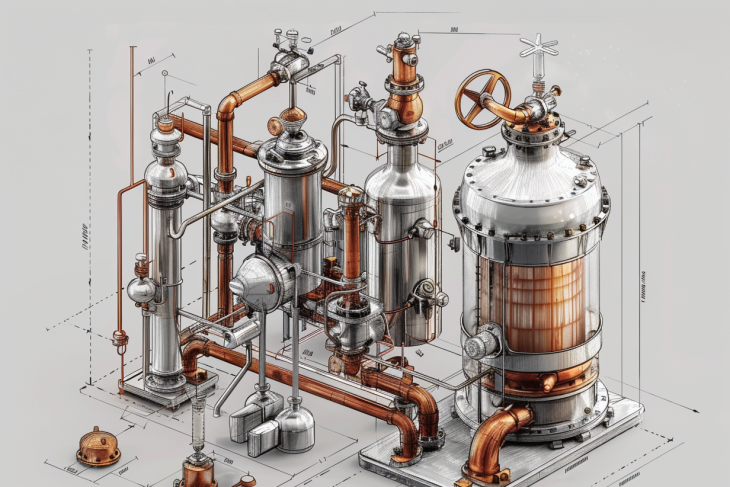

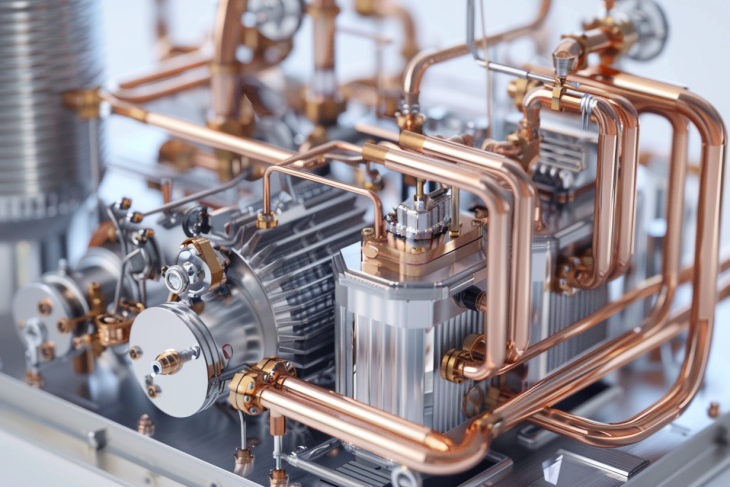

A single-effect evaporator is the simplest form of evaporator. It consists of a single evaporating unit where the solution is heated, and the solvent is evaporated. The vapor generated is then condensed to separate it from the concentrated solution. The primary components of a single-effect evaporator include a heat exchanger, a separator, and a condenser.

Advantages

1. **Simplicity**: Single-effect evaporators are straightforward in design and operation, making them easy to understand and maintain.

2. **Lower Initial Cost**: Due to their simple design, single-effect evaporators typically have a lower initial cost compared to multiple-effect evaporators.

3. **Flexibility**: They are suitable for small-scale operations and can handle a wide range of solutions and solvents.

Disadvantages

1. **Low Energy Efficiency**: Single-effect evaporators are not energy-efficient because they do not utilize the latent heat of the vapor generated. The heat is often lost, leading to higher energy consumption.

2. **Higher Operating Costs**: Due to their low energy efficiency, single-effect evaporators have higher operating costs, especially in large-scale operations.

Multiple-Effect Evaporators

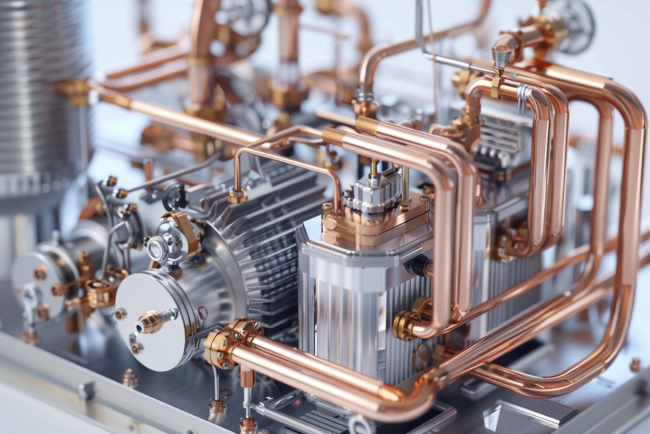

Definition and Working Principle

Multiple-effect evaporators consist of a series of single-effect evaporators, known as effects, connected in such a way that the vapor from one effect is used as the heating medium for the next effect. This cascading use of vapor significantly improves the energy efficiency of the evaporation process. Typically, multiple-effect evaporators have three to seven effects.

Advantages

1. **High Energy Efficiency**: By utilizing the vapor from one effect to heat the next, multiple-effect evaporators significantly reduce energy consumption. This makes them much more energy-efficient compared to single-effect evaporators.

2. **Lower Operating Costs**: The improved energy efficiency translates to lower operating costs, making multiple-effect evaporators more cost-effective in the long run, especially for large-scale operations.

3. **Scalability**: Multiple-effect evaporators are suitable for large-scale industrial applications due to their high efficiency and ability to handle large volumes of solution.

Disadvantages

1. **Complexity**: The design and operation of multiple-effect evaporators are more complex compared to single-effect evaporators. This complexity requires skilled operators and more rigorous maintenance.

2. **Higher Initial Cost**: The initial cost of multiple-effect evaporators is higher due to their complex design and additional components.

3. **Space Requirements**: Multiple-effect evaporators require more space due to the multiple stages involved in the process.

Comparison of Single-Effect and Multiple-Effect Evaporators

Energy Efficiency

Energy efficiency is one of the most significant differences between single-effect and multiple-effect evaporators. Single-effect evaporators have low energy efficiency because they do not reuse the vapor’s latent heat. In contrast, multiple-effect evaporators reuse the vapor’s latent heat from one effect to the next, significantly improving energy efficiency.

Operating Costs

Due to their low energy efficiency, single-effect evaporators have higher operating costs, especially for large-scale operations. Multiple-effect evaporators, with their higher energy efficiency, have lower operating costs, making them more cost-effective in the long run.

Initial Costs

Single-effect evaporators have lower initial costs due to their simple design. Multiple-effect evaporators have higher initial costs because of their complex design and additional components.

Complexity and Maintenance

Single-effect evaporators are simpler to operate and maintain. Multiple-effect evaporators are more complex and require skilled operators and more rigorous maintenance.

Applications

Single-effect evaporators are suitable for small-scale operations and applications where energy costs are not a significant concern. Multiple-effect evaporators are ideal for large-scale industrial applications where energy efficiency and operating costs are critical factors.

Conclusion

In summary, the choice between single-effect and multiple-effect evaporators depends on various factors, including the scale of operation, energy costs, and budget. Single-effect evaporators are simpler and have lower initial costs, making them suitable for small-scale operations. However, they have higher operating costs due to low energy efficiency. Multiple-effect evaporators, on the other hand, are more complex and have higher initial costs but offer significant energy savings and lower operating costs, making them ideal for large-scale industrial applications. Understanding these differences is crucial for selecting the right evaporator for specific industrial needs.